2BE3 series water ring vacuum pump and compressor

2BE3 series water ring vacuum pumps and compressors are high-efficiency and energy-saving products developed by our company combined with the advanced technology of international congeneric products. They are usually used to suck gas that does not contain solid particles, is insoluble in water, and is non-corrosive, so as to form a vacuum in a closed container and pressure.

Key words:

Category:

2BE3 series water ring vacuum pump and compressor

Tel:

2BE3 series water ring vacuum pump and compressor

Details

Product introduction

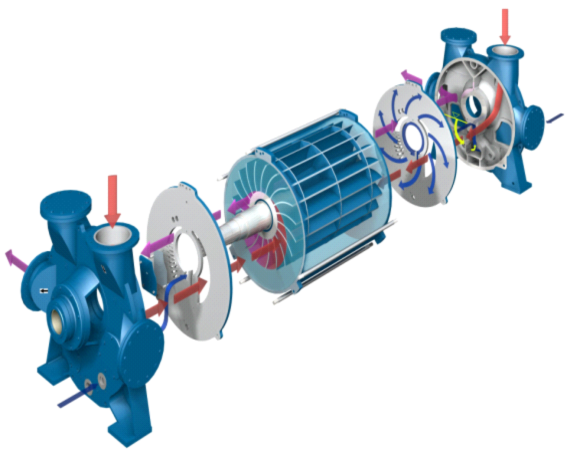

2BE3 series water ring vacuum pumps and compressors are high-efficiency and energy-saving products developed by our company combined with the advanced technology of international congeneric products. They are usually used to suck gas that does not contain solid particles, is insoluble in water, and is non-corrosive, so as to form a vacuum in a closed container and pressure. By changing the structural materials and adding anti-corrosion coatings, it can also be used to suck corrosive gases or use corrosive liquids as working fluids. It is very suitable for long-term, continuous operation. 2BE3 series products have been designed with full consideration that it must be able to extract a variety of gases.

2BE3 can be used with various drive devices, such as belt drive, gearbox, synchronous motor, variable frequency governor, etc. In addition, in order to save space, a series operation mode driven by one motor can also be adopted. It has been widely used in papermaking, coal mine, power plant, vacuum filtration, chemical industry, petrochemical industry, food processing and other industries.

Features

● This series of pumps adopts a single-stage and single-acting structure, which has the advantages of simple structure, convenient maintenance, reliable operation, high efficiency and energy saving, and can adapt to harsh working conditions such as large displacement and load shock waves.

● Unique and flexible suction and exhaust port optimization design, allowing upper and side exhaust methods, easy to install on site. In limited installation space, 2BE3 can be installed with an upper separator, reducing the floor space and eliminating the need for trenches.

● The impeller is welded and treated with high temperature solidification and melting, and the blade is punched, formed and shaped at one time. The impeller and the pump shaft adopt hot-installed interference fit, which has reliable performance and stable operation. Can adapt to the harsh working conditions of load shock waves.

● Through the optimized design of the disc and impeller, the internal fluid backflow efficiency is improved, and the energy saving reaches 6 to 8%. The effect is obvious.

● The supply range of pumps can be flexibly selected according to customer requirements:

Pump head: including top-mounted separator and connecting pipe.

Complete-built unit: including pump head, top-mounted separator, connecting pipe, motor, chassis, shield, electric pump coupling or electric pump pulley, belt.

Vacuum pump unit: including vacuum pump complete-built unit, gas-water separator, one-way valve, bellows and connecting pipelines, electric contact vacuum gauge, self-coupling vacuum starting cabinet.

Complete set of equipment: including complete-built unit pump, gas-water separator (with liquid level gauge), heat exchanger, valve, normally closed valve, filter, vacuum gauge, pressure gauge, pipeline, electric control cabinet.

● Various transmission modes, such as: coupling drive, pulley drive, gear reducer drive.

● According to the corrosiveness of the medium, special materials can be provided: 304, 316L, duplex stainless steel and other materials; according to customer needs, various sealing methods such as packing seal and mechanical seal can be provided.

■ application field

2BE3 series water ring vacuum pumps and compressors are widely used in papermaking, chemical industry, petrochemical, light industry, pharmaceutical, food, building materials, electrical appliances, coal washing, mineral processing, fertilizer and other industries, and their operation reliability is well-known. In the coal industry, it can especially discharge highly flammable and explosive gases, such as gas and methane. It can be designed and installed in the ground gas drainage station, and can be equipped with a mobile gas drainage system.

2BE3 water ring vacuum pump performance table

| Model | speed (Transmission mode) r/min | Maximum shaft power kW | Motor power kW | Maximum pumping rate | ultimate vacuum (Absolute pressure) mbar | Pump head weight (Including top separator) kg | |

| m3/h | m3/min | ||||||

| 2BE3 400 | 340(Belt/gear reducer) 390(Belt/gear reducer) 440(Belt/gear reducer) 490(Belt/gear reducer) 530(Belt/gear reducer) 570(Belt/gear reducer) 610(Belt/gear reducer) | 82 95 115 134 148 167 189 | 110 110 132 160 185 200 220 | 4850 5650 6250 6900 7470 8000 8600 | 80.8 94.2 104.2 115.0 124.5 133.3 143.3 | 160 | 3275 |

| 2BE3 420 | 340(Belt/gear reducer) 390(Belt/gear reducer) 440(Belt/gear reducer) 490(Belt/gear reducer) 530(Belt/gear reducer) 570(Belt/gear reducer) 610(Belt/gear reducer) | 108 132 157 180 204 229 260 | 132 160 185 200 220 250 315 | 6650 7650 8550 9400 10150 10700 11600 | 110.8 127.5 142.5 156.6 169.2 178.3 193.3 | 160 | 3720 |

| 2BE3 500 | 260(Gear reducer) 300(Gear reducer) 340(Gear reducer) 380(Gear reducer) 420(Gear reducer) 470(Gear reducer) | 142 171 203 238 277 338 | 160 200 250 280 315 400 | 8700 10150 11400 12700 13800 15500 | 145.0 169.2 190.0 211.7 230.0 258.3 | 160 | 6110 |

| 2BE3 520 | 260(Gear reducer) 300(Gear reducer) 340(Gear reducer) 380(Gear reducer) 420(Gear reducer) 470(Gear reducer) | 172 210 245 288 337 412 | 200 250 280 315 400 500 | 10700 12300 14000 15400 16800 18700 | 178.3 205.0 233.3 256.7 280.0 311.7 | 160 | 6740 |

| 2BE3 600 | 230(Gear reducer) 260(Gear reducer) 290(Gear reducer) 320(Gear reducer) 350(Gear reducer) 400(Gear reducer) | 205 243 285 322 365 465 | 250 280 315 355 450 560 | 12700 14400 16000 17500 19000 21600 | 211.7 240.0 266.7 291.7 316.7 360.0 | 160 | 9100 |

| 2BE3 620 | 230(Gear reducer) 260(Gear reducer) 290(Gear reducer) 320(Gear reducer) 350(Gear reducer) 400(Gear reducer) | 250 300 340 390 450 570 | 280 355 400 450 500 630 | 15600 17700 19500 21300 23200 26200 | 260.0 295.0 325.0 355.0 386.7 436.7 | 160 | 10700 |

| 2BE3 670 | 210(Gear reducer) 240(Gear reducer) 270(Gear reducer) 300(Gear reducer) 320(Gear reducer) 330(Gear reducer) 370(Gear reducer) | 280 350 415 465 523 545 670 | 315 400 450 560 630 630 800 | 18300 20400 23160 25500 27000 27720 30960 | 305 340 386 425 450 462 516 | 160 | 12700 |

| 2BE3 720 | 190(Gear reducer) 210(Gear reducer) 240(Gear reducer) 270(Gear reducer) 300(Gear reducer) 340(Gear reducer) | 345 395 475 550 642 795 | 400 450 560 630 710 900 | 21900 24300 27480 30540 33780 38100 | 365 405 458 509 563 635 | 160 | 15700 |

Note: 1. The power of the motor selected above can work under most working conditions. If the exhaust port pressure is high (gauge pressure 0.02~ 0.05MPa), the motor power should be increased accordingly; if the working pressure of the actual 2BE3 vacuum pump corresponds to a smaller shaft power (refer to the shaft power curve), the motor power close to the shaft power can also be selected, which can save more energy.

2. The above vacuum pump speed is the reference speed, and the actual speed is determined according to the transmission mode and customer requirements.

3. 2BE3 400/420 belt drive can choose the speed: 327/349/393/446/475/498/527rpm.

4. Belt drive is not recommended for vacuum pumps above 2BE3 500.

5, gear reducer drive installation size to determine the speed, gear reducer manufacturer to determine.

Previous page

无

Next page

Related Products