VDP series variable pitch screw vacuum pump

VDP series variable pitch screw vacuum pump adopts advanced three-stage variable pitch rotor profile, high efficiency and energy saving, reliable operation, ultimate vacuum up to 1.33Pa, can work efficiently and continuously under any pressure between atmospheric pressure and ultimate pressure.

Key words:

Category:

VDP series variable pitch screw vacuum pump

Tel:

VDP series variable pitch screw vacuum pump

Details

overview

VDP series variable pitch screw vacuum pump adopts advanced three-stage variable pitch rotor profile, high efficiency and energy saving, reliable operation, ultimate vacuum up to 1.33Pa, can work efficiently and continuously under any pressure between atmospheric pressure and ultimate pressure.

VDP series adopts variable pitch dry screw technology, the compression chamber does not need water or any other working medium, avoids the condensation and deposition of the pumped medium, and prevents the medium from being polluted by oil and water, and can obtain a clean vacuum. Widely used in solvent recovery, vacuum drying, vacuum distillation and other processes in the fields of pharmaceuticals, electronics, chemicals, and food processing.

Technical Features

Inhalation efficiency increased by 15%

Ultimate vacuum up to 1.33Pa

Three-stage variable pitch, energy saving up to 35%

High efficiency jacket water cooling reduces exhaust temperature by 50%

G1 rotor dynamic balance, low noise, low vibration, no inertia force, high speed operation and stable operation

Simple structure, easy maintenance, low maintenance cost, long life

Optional mechanical seal, lip seal, simple structure, reliable seal, ensure zero leakage and no fault

Good corrosion resistance, medium contact parts can be sprayed with Hastelloy coating, Teflon coating, nickel-based tungsten carbide coating

Under strong corrosion conditions, the materials of parts such as pump body and screw that contact materials can be duplex stainless steel, 316L stainless steel, etc

Wide operating range, continuous operation at any pressure between atmospheric pressure and ultimate pressure

It can be used in series with roots pump, molecular pump, etc., to obtain high pumping speed under high vacuum conditions.

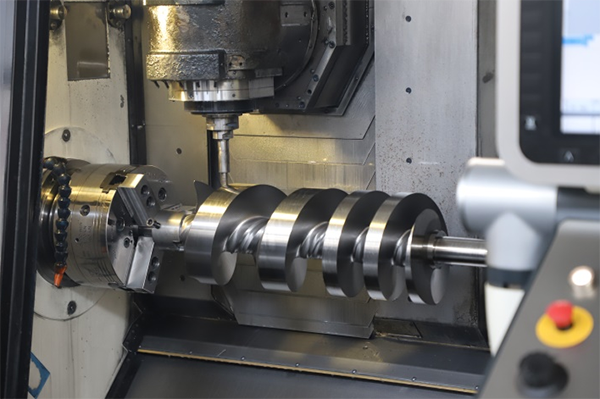

How it works

It is a variable pitch twin-screw vacuum pump. A pair of screw rotors rotate in the cavity. The pumped medium is captured by the screw and sent to the exhaust port after compression. During the compression process, the screw rotors do not contact each other or the cavity body. The compression chamber does not require lubricating oil or working fluid. The cooling method can be either direct water cooling or air-cooled heat exchanger to achieve radiator cooling. Due to the wide range of optional technical solutions and accessories, the VDP series screw vacuum pumps can be very well adapted to various process requirements. All product lines include seven sizes, with rated pumping speeds ranging from 200 cubic meters to 3,000 cubic meters per hour.

Structural advantage

The variable pitch screw vacuum pump has been favored by more and more users due to its wide pumping speed range, simple and compact structure, frictionless air extraction chamber components, long life, low energy consumption, no water and no oil pollution. The variable pitch screw vacuum pump can truly ensure a clean pumped space without polluting the surrounding environment, and is known as the 21st century green vacuum pump.

It can be used in both the semiconductor industry and the petrochemical industry. It can be widely used in electronics, nuclear energy, chemical industry, medicine, food industry and other fields. In the semiconductor industry, it is used for the production of wafers, the manufacture of liquid crystal displays, etching, and CVD processes; in the nuclear industry, it is used for nuclear reactors and nuclear industry vacuum acquisition; in the chemical industry, it is used for vacuum distillation and solvent extraction to recover solvents with high efficiency, and in the production of fatty acids, it is used to eliminate water pollution and remove obstruction in ejectors; in the pharmaceutical industry, it is used to recover pharmaceutical liquids and pharmaceutical intermediates, provide clean and sterile conditions for the production of artificial organs, and recover gas disinfectants; in the food industry, it is used for fragrances, flavor concentration, food packaging, etc. The application range is extremely wide, and the product market prospect is promising.

The Roots-screw vacuum unit based on the variable pitch screw vacuum pump can replace the traditional Roots-water ring vacuum system and is widely used in the pharmaceutical, chemical and food industries. It has the advantages of small footprint, low energy consumption, long life, good reliability, and no water vapor influence. It is suitable for the removal and transportation of various gases.

Advantages and Features

● Excellent vacuum processing capacity: 100-3000m3/Hr.

● Do not use oil and water, will not cause oil and water pollution.

● Low power consumption, low noise, low vibration, good dynamic balance, no inertial force, high-speed operation.

● Simple design structure, easy maintenance, low maintenance cost, no wearing parts, long life.

● Wide range of applications, with high vacuum performance.

● Long service life, corrosion-resistant coating on gas contact parts.

● Mechanical seal or lip seal can be selected, the seal is reliable and will not fail frequently due to pollution, and the bearing is durable.

● Coating standard: corrosion-resistant and heat-resistant Hastelloy, Teflon, nickel-based tungsten carbide

■ Standard accessories:

Base and Shield

Exhaust muffler and intake separator

filter

Flow switch

check valve

vacuum gauge

■ Optional accessories:

Recycling tank

Exhaust condenser

Inlet vacuum buffer tank

temperature switch

Scope of application

● The application of variable pitch screw pump in semiconductor synthesis and liquid crystal production mainly includes semiconductor plasma enhanced vapor phase precipitation (PECVD) and reflected ion etching (RIE) processes, liquid crystal production etching process and CVD process for producing TFT screen plasma (PLASMA). This process requires a backflow of 0 to protect the workpiece from contamination.

● The application of variable pitch screw pump in petrochemical industry is mainly to extract condensable gas, or toxic gas, or corrosive gas, or gas containing fine dust.

● Pharmaceutical industry, used for vacuum drying of drugs, recovery of drug intermediates, recovery of gas disinfectants, providing clean and sterile conditions for artificial organs, etc.

● Used in chemical industry for vacuum distillation and solvent extraction and recovery, such as extraction and recovery of acetone, polyol and other processes

● Industrial exhaust; centralized vacuum treatment system

● The mixing process of the extruder and the exhaust process of the plate

● Mixed resin deodorization process; used in fatty acid production to eliminate water pollution and blockages in injectors.

● All applications involving oil-free and water-free vacuum treatment

● The food industry is used for fragrances, flavor concentrates, etc.

Technical parameters

|

Model |

Pumping volume |

ultimate pressure |

Motor power |

speed |

intake |

exhaust |

Cooling water volume |

noise |

weight |

|

M³/h |

Pa |

KW |

rpm |

mm |

mm |

L/min |

dB |

Kg |

|

|

VDP-200 |

165 |

1.33 |

5.5 |

2900 |

50 |

40 |

10 |

75 |

250 |

|

VDP-320 |

260 |

1.33 |

5.5 |

2900 |

50 |

40 |

10 |

75 |

320 |

|

VDP-430 |

360 |

1.33 |

7.5 |

2900 |

65 |

50 |

15 |

78 |

380 |

|

VDP-650 |

550 |

1.33 |

11 |

2930 |

80 |

65 |

15 |

78 |

480 |

|

VDP-900 |

750 |

1.33 |

15 |

2930 |

100 |

80 |

20 |

80 |

600 |

|

VDP-1500 |

1250 |

1.33 |

30 |

2950 |

125 |

100 |

30 |

82 |

980 |

|

VDP-3000 |

2500 |

1.33 |

55 |

2950 |

200 |

125 |

40 |

82 |

1350 |

Previous page

无

Next page

Related Products